Wheel Spacer Durability Calculator

Estimate Your Spacer Lifespan

Your Results

Estimated Lifespan

Key Findings

Wheel spacers don’t last forever. They’re not meant to be lifelong parts like your engine or transmission. But they also don’t just wear out after a few months. How long they last depends on three things: how they’re made, how they’re installed, and what you drive them on. If you get this right, a good set of spacers can easily last 10 years or more. If you cut corners, they might fail in under a year.

What Wheel Spacers Are Made Of Matters Most

Not all spacers are created equal. You’ll see them made from aluminum, steel, or even cheap cast zinc. The good ones? They’re forged from 6061-T6 aluminum. That’s the same high-strength alloy used in aircraft landing gear. It’s lightweight, corrosion-resistant, and holds up under stress. These spacers are machined to exact tolerances - no warping, no uneven surfaces.

On the flip side, cheap spacers made from die-cast zinc or low-grade aluminum? They’re brittle. They crack under pressure. I’ve seen them split apart after just 20,000 kilometers on rough roads. One guy in Geelong bought a $40 set off eBay. He drove them for eight months, then heard a loud clang on the highway. Turned out, one spacer had fractured clean in half. His wheel was wobbling. He got lucky - no accident.

Installation Is Non-Negotiable

Even the best spacer won’t last if it’s installed wrong. The biggest mistake? Not torquing the bolts properly. You can’t just tighten them by hand. You need a torque wrench. Most manufacturers recommend 85-100 Nm for standard spacers. Too loose? The spacer shifts. Too tight? You strip the studs or warp the hub.

Another common error? Skipping hub-centric rings. Spacers that fit loosely over the hub create play. That play means vibration. Vibration means stress. Stress means cracks. A hub-centric ring ensures the spacer sits perfectly centered on the axle. No wobble. No uneven load. Just clean, stable rotation.

And don’t forget the bolts. Always use grade 10.9 or higher. Steel bolts. Not the flimsy zinc-plated ones that come in cheap kits. I’ve seen spacers fail because the bolts snapped. That’s not the spacer’s fault - it’s the installer’s.

Driving Conditions Change Everything

If you drive on smooth highways, your spacers will last longer. If you drive on gravel roads, potholes, or off-road trails? They’ll take more punishment. Every impact transfers force through the spacer. Over time, that adds up.

One customer in Ballarat runs a lifted 4WD with 35-inch tires and 25mm spacers. He hits dirt tracks weekly. He checks his spacers every 10,000 km. So far, after 60,000 km, they’re still solid. No cracks, no play. Why? Because he uses forged spacers, torques everything right, and replaces bolts every 30,000 km.

Compare that to someone in the city who uses 15mm spacers on a sedan and drives only on paved roads. Their spacers might never show wear. But if they never check them? That’s dangerous. Corrosion can creep in. Rust between the spacer and hub can cause uneven pressure. That’s how you get a warped rotor or a loose wheel.

Signs Your Spacers Are Wearing Out

You don’t need a mechanic to spot trouble. Look for these signs:

- Unusual vibrations at highway speeds

- Uneven tire wear - especially on the outer edges

- Noises like clunking or rattling when turning or going over bumps

- Visible cracks, rust, or deformation on the spacer surface

- Loose lug nuts, even after retightening

These aren’t normal. If you see any of these, stop driving. Get the spacers inspected. Don’t wait until your wheel comes off.

How Often Should You Check Them?

Check your spacers every 5,000 to 10,000 km. That’s about every oil change. Here’s what to do:

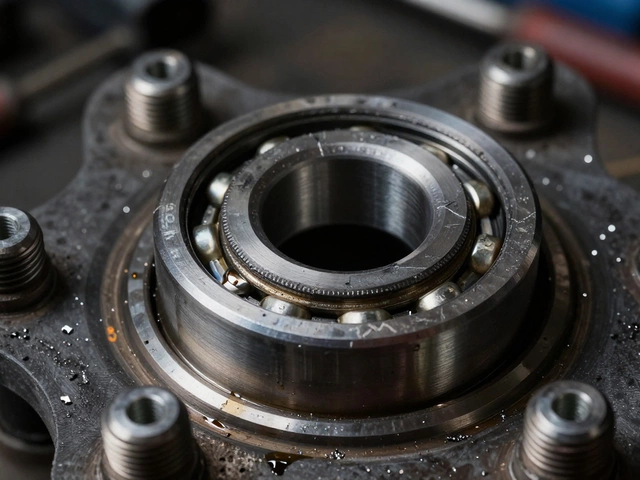

- Remove the wheel and clean the spacer and hub surface

- Look for cracks, corrosion, or warping

- Check if the spacer spins freely on the hub (it shouldn’t - it should be flat and tight)

- Inspect the bolts for stretching or thread damage

- Reinstall with fresh thread locker and torque to spec

Replace bolts every 30,000 km. Even if they look fine, metal fatigue sets in. A stretched bolt won’t hold torque. That’s how failures happen.

What Happens When Spacers Fail?

It’s not just a noise. It’s not just a repair bill. It’s a safety risk. A failed spacer can cause:

- Loss of wheel control at high speed

- Damage to brake calipers or suspension components

- Complete wheel detachment

There are documented cases of vehicles losing wheels because of spacer failure. In Australia, Transport for NSW has issued warnings about aftermarket spacers that don’t meet AS/NZS 1301 standards. The ones that do? They’re stamped with a certification mark. Always look for that.

How Long Should You Expect Them to Last?

Here’s the real answer: 10 to 15 years if you use quality spacers, install them right, and check them regularly. But that’s not a guarantee. It’s a best-case scenario.

Most people who install cheap spacers and never check them? They last 2-5 years - if they’re lucky. Many fail before 10,000 km.

There’s no expiration date stamped on them. But there is a pattern. The ones that last are the ones treated like critical safety parts - because they are.

What to Buy and What to Avoid

Stick with brands that are known in the performance community: H&R, ECS Tuning, BONOSS, or RSD. They use 6061-T6 aluminum, include hub-centric rings, and provide torque specs. They also offer warranties.

Avoid anything sold as a “universal fit” with no brand name. If the packaging says “fits most cars” and has no model-specific data? Walk away. If it’s under $50 for a set? That’s a red flag. You’re not saving money - you’re risking your life.

Final Thought: They’re Not Accessories. They’re Safety Gear.

Wheel spacers aren’t like a spoiler or LED lights. They’re part of your wheel assembly. They carry weight. They handle forces. They’re under constant stress. Treat them like your brakes. Check them. Maintain them. Replace them when needed. A $150 set of quality spacers, properly installed, might be the cheapest safety upgrade you ever make.

Can wheel spacers cause wheel bearing failure?

Yes, improperly installed or low-quality spacers can increase stress on wheel bearings. When a spacer isn’t perfectly centered or is too thick, it changes the load angle on the bearing. This leads to premature wear. You’ll notice it as a grinding noise or vibration that gets worse over time. Always use hub-centric spacers and proper torque to minimize this risk.

Do wheel spacers affect alignment?

Spacers themselves don’t change your alignment angles - but they do change the track width. That can make tire wear patterns more noticeable if your alignment was already off. After installing spacers, it’s smart to get a full alignment check. Especially if you’re running wider-than-stock setups. You don’t want uneven tire wear from bad toe or camber.

Are wheel spacers legal in Australia?

Yes, but only if they meet AS/NZS 1301 standards and are installed correctly. Some states require certification or inspection if the spacer changes the vehicle’s track width by more than 25mm. Always check with your local transport authority. Using uncertified spacers can void your insurance and lead to fines during roadside inspections.

Can I use spacers on my daily driver?

Absolutely - if you use quality parts and maintain them. Many daily drivers use 10-15mm spacers to improve stability or fit wider tires. The key is regular checks. If you’re driving 20,000 km a year, inspect them at least twice a year. Don’t assume they’re fine because they look okay. Corrosion and micro-cracks can hide under dirt.

Do thicker spacers wear out faster?

Thicker spacers don’t necessarily wear out faster - but they do increase leverage on the wheel hub and studs. That means more stress on every component. A 30mm spacer puts more strain on the bolts and bearings than a 10mm one. That’s why high-performance spacers over 20mm are always made from stronger materials and require upgraded hardware. Never go thicker than recommended for your vehicle model.