Carbon Fiber Durability: What Makes It Strong and How to Keep It Looking New

Carbon fiber looks like the future of car styling – light, sleek, and super strong. But does it live up to the hype when you drive daily, wash, or hit a pothole? Below we break down the real durability of carbon fiber and give you practical tips to protect it, whether it’s a spoiler, a hood, or a wrap accent.

Why Carbon Fiber Is Tough (And Where It Shows Its Weak Spots)

Carbon fiber gets its strength from a woven fabric of carbon strands that are bonded with resin. The result is a material that’s up to five times stronger than steel for the same weight. That’s why manufacturers love it for performance parts. However, the resin can be vulnerable to surface damage. Scratches, UV exposure, and harsh chemicals can weaken the outer layer, eventually leading to delamination or cracks.

Everyday Things That Can Hurt Carbon Fiber

Most owners think carbon fiber is indestructible, but everyday habits can chip away at it. A high‑pressure car wash nozzle can erode the resin if you use the wrong spray angle. Road salt, especially in winter, can seep into tiny cracks and cause corrosion under the surface. Even a cheap silicone‑based cleaner can leave a film that attracts dirt, making the part look dull and encouraging abrasion.

Another surprise: heat. While carbon fiber tolerates high temperatures, prolonged exposure to direct sunlight can cause the resin to soften over time. This is why you’ll often see carbon fiber parts with a clear coat – it acts like a shield against UV rays and heat.

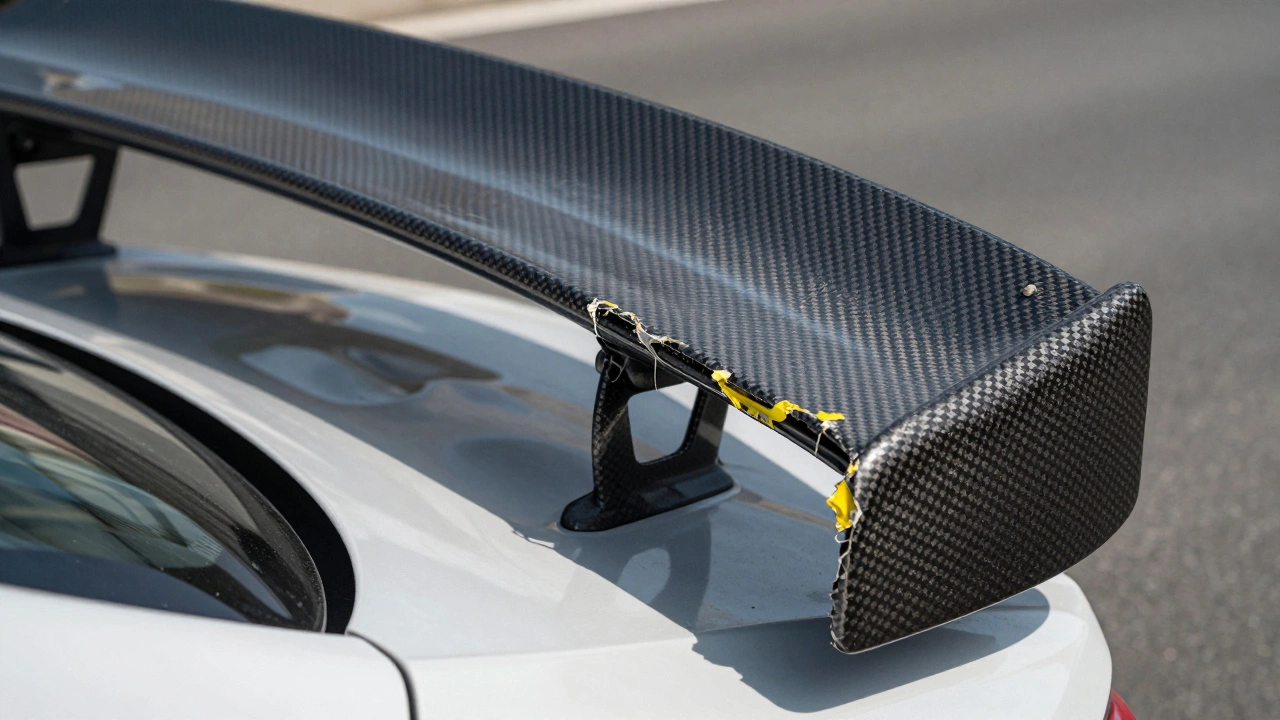

Finally, impact matters. A small rock hitting a carbon fiber hood may leave a barely visible nick, but that nick can grow into a crack if the area is repeatedly flexed. The key is to catch those marks early and treat them before they spread.

Simple Ways to Keep Carbon Fiber Looking Fresh

Start with a gentle hand wash. Use a microfiber mitt, lukewarm water, and a pH‑balanced car shampoo. Avoid abrasive sponges and high‑pressure jets. Rinse slowly to let water flow off the fiber rather than forcing it into seams.

Dry with a soft microfiber towel. If you need extra protection, apply a high‑quality, non‑wax carbon fiber spray sealant. These products create a thin, invisible layer that repels water, UV, and contaminants without changing the finish.

Check for scratches regularly. A quick inspection after a wash can reveal tiny chips. Lightly sand the area with 1500‑grade sandpaper, then use a carbon fiber repair kit to fill and rebuild the resin. Finish with the sealant for added protection.

If you live in a salty climate, rinse your car often during winter. A fresh water rinse removes salt before it sits and eats away at the resin. For parking under the sun, use a car cover or park in shade whenever possible.

When Professional Help Makes Sense

Some carbon fiber parts, like large spoilers or custom wraps, need more than a DIY fix. At Nottingham Car Wraps & Styling we offer professional polishing, clear‑coat application, and full‑body carbon fiber refurbishment. Our team knows the right products that won’t react with the resin, keeping the part’s strength intact while giving it a showroom shine.

Getting a pro to re‑coat a damaged piece can save you from costly replacements later. It also ensures the finish matches the rest of your vehicle, preserving the overall aesthetic.

In short, carbon fiber is incredibly durable when you treat it right. Regular gentle cleaning, UV‑protective sealants, and quick attention to scratches will keep your parts strong and glossy for years. If you ever doubt your DIY skills, a quick visit to a specialist can keep the carbon fiber looking as good as the day it was installed.